Using and Driving a Solenoid

A solenoid is a coil that pulls (or

pushes) a metal rod called

a plunger when current flows through it. There are many kinds of

solenoids: pull and push types, with and without springs (to push back

the plunger when current no longer flows), with and without latches,

etc. The main advantage of solenoids over motors is that they can

effect a linear motion using a compact mechanism with no gears. On the

negative side, solenoids have a very short stroke (the length of

movement of the plunger).

A solenoid is a coil that pulls (or

pushes) a metal rod called

a plunger when current flows through it. There are many kinds of

solenoids: pull and push types, with and without springs (to push back

the plunger when current no longer flows), with and without latches,

etc. The main advantage of solenoids over motors is that they can

effect a linear motion using a compact mechanism with no gears. On the

negative side, solenoids have a very short stroke (the length of

movement of the plunger).

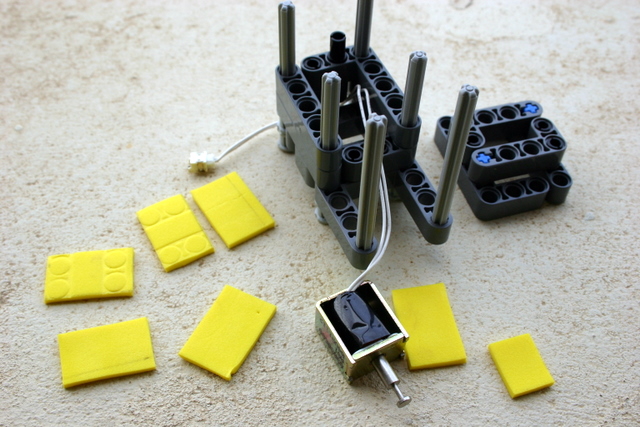

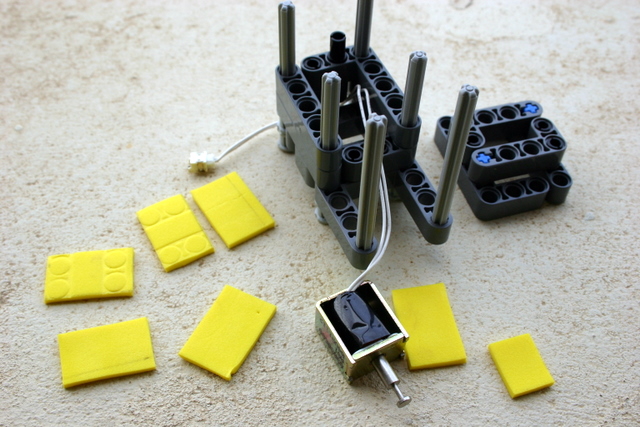

In this project I tried to utilize a small solenoid that I

removed from an old Iomega 100MB Zip drive. The solenoid itself, which

you can see in the picture below, is smaller than 2x3x3 Lego units. It

is a

pull-type solenoid with no spring to push the plunger back out. The

plunger ends with a wide disk that is designed to pull something with

it. The resistance of the coil is only 3.6Ohm, so if you connect it to

a 9V supply, it will draw 2.5A (after a ramp-up period).

The next few paragraphs explain how to integrate the solenoid

into a Technic structure, how to use it to fire the Technic cannon (a

spring-loaded Technic part that fires a little missile with a foam head

when you pull back a trigger axle), and how to drive the solenoid from

the NXT, either using a motor port (really easy) or a sensor port (more

challenging).

A video

shows the sensor-port activated solenoid in action: the mechanism

charges for 15 seconds and then fires. You can of course wait for some

external event before firing, like detecting a sound or a nearby object.

Warning: connecting your NXT to any home-made

gizmo (like the

one described here) can damage it. Beware.

Integrating the Solenoid into a Technic Construction

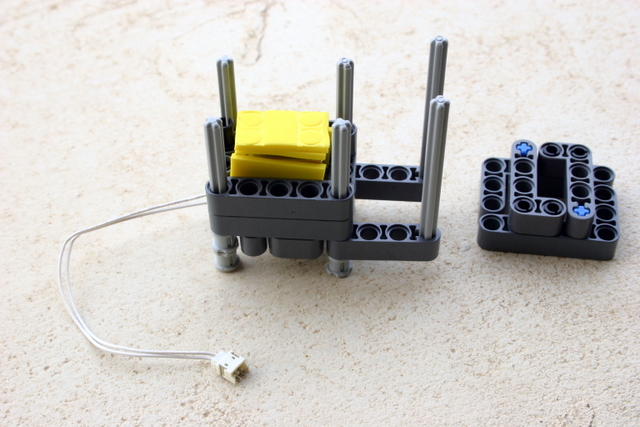

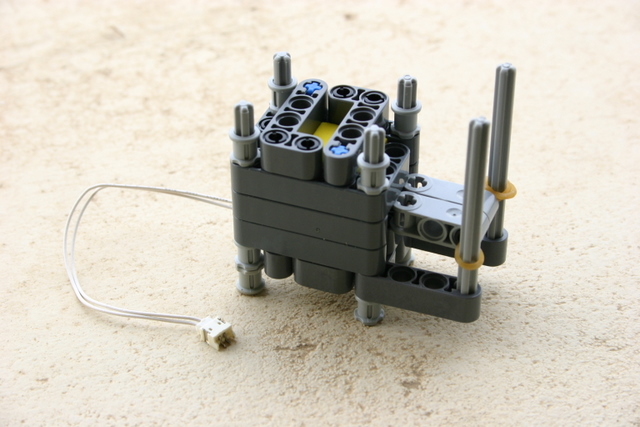

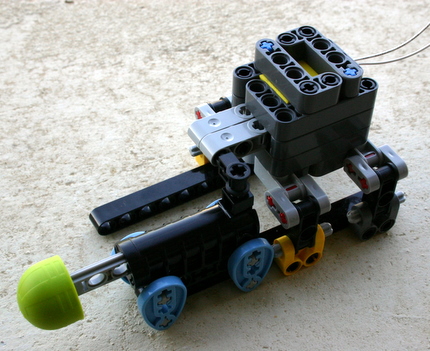

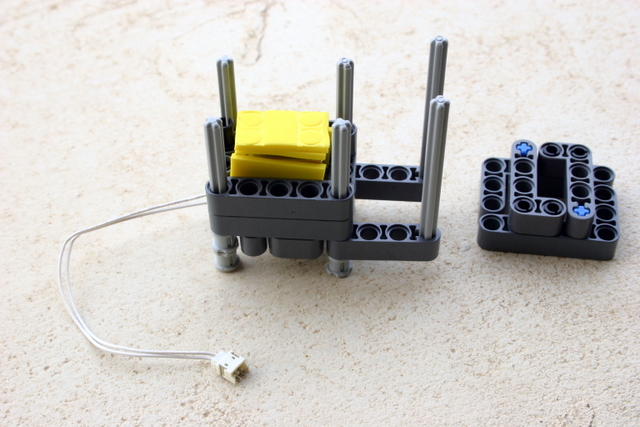

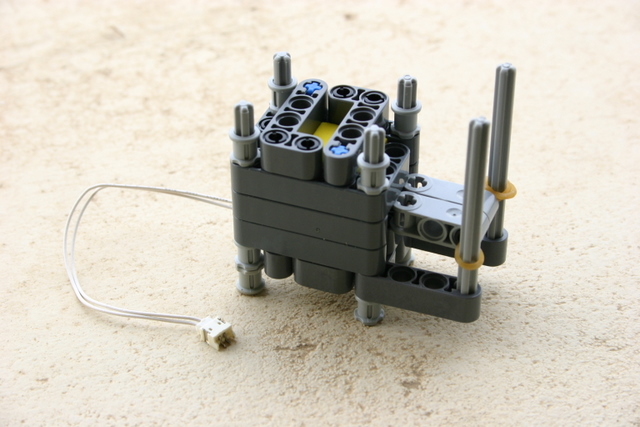

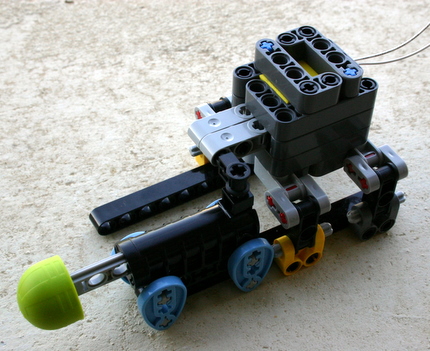

The first step was to integrate the solenoid into a Technic

contruction. I ended up encasing it in a Technic box with a 2x3x3

cavity with a slot in front for the plunger. To make the fit tight, I

used cut-to-size pieces of thin craft foam (about 1mm).

Fortunately, the little disk at the end of the plunger fits

very nicely

into the slots in the axle joiners, so I used them as a Technic

extension of the plunger. I initially used a rubber band to pull back

the plunger (but see below for a better idea).

The useful travel of the plunger is about 1/2 Lego unit. If

you pull it by more that this, the solenoid might not be able to pull

it back. This is not much. Here is the whole thing together.

An alternative construction might be to encase the solenoid in

two 2x3 bricks stacked one on top of the other and hollowed out. This

would be much more compact than the Technic box that I constructed. You

would need to close off the bottom with a 2x3 plate, but the studs of

the plate might not leave enough vertical room for the solenoid (but I

didn't try). A potential disadvantage of this costruction is that the

front wall of the bricks might further limit the movement of the

plunger, which is short anyway.

Using the Solenoid/Technic Combination

It took me a while to figure out what this construction is

good for. The stroke of the plunger is short, and to keep the

plunger pulled requires a lot of current. These considerations rule out

many potential applications, like activating a pneumatic valve (this is

a common use for solenoids, but this particular solenoid is a poor fit

fot the Lego pneumatic valves).

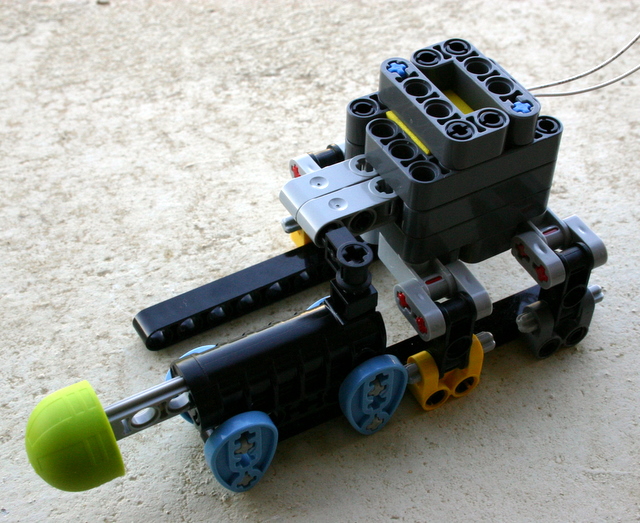

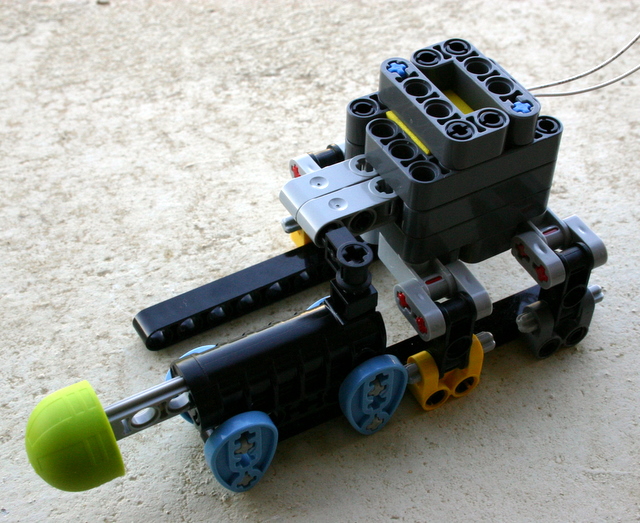

Then I remembered that there is one Technic mechanism that is

activated by a small momentary movement: the Technic competition

cannon. As it turns out, the solenoid is perfect for

triggering the Technic cannon.

The one difficulty is mounting the cannon so that the solenoid

can trigger it. I had to offset the solenoid mechanim and the cannon by

half a stud in two dimentions, which is what the cams and the "Technic

Axle Joiners Perpendicular Double Split" are used for. The plunger

assembly pulls a "Technic Pole Reverser Handle" that is mounted on the

cannon's triger axle; the handle is not pushed all the way on the

trigger, but there is a gap of about 1/4 of a unit to keep the plunger

horizontal.

Driving the Solenoid

I connected the solenoid to one of the NXT's motor ports (more

specifically to port A) in series with 2 resistors of 1Ohm nominal

resistance each. The resistors were a little higher than specified,

about

2.5Ohm total. I am not sure that they are necessary, but I felt that

this would be safer than connecting a coil with only 3.6Ohm resistance

directly to the motor port. With the resistors the total resistance is

more than 6Ohm, which limits the port's current to less than 1.5A.

I activated the solenoid by turning on Port A at 100%

power for 10ms. This activates the solenoid reliably and fires the

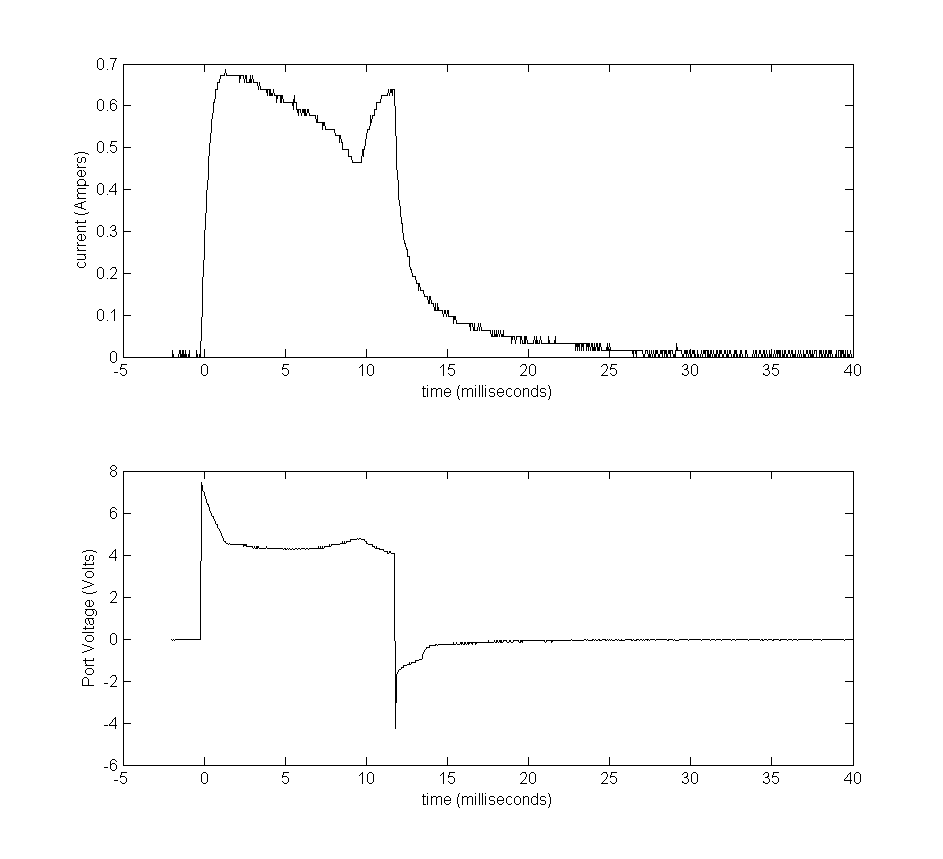

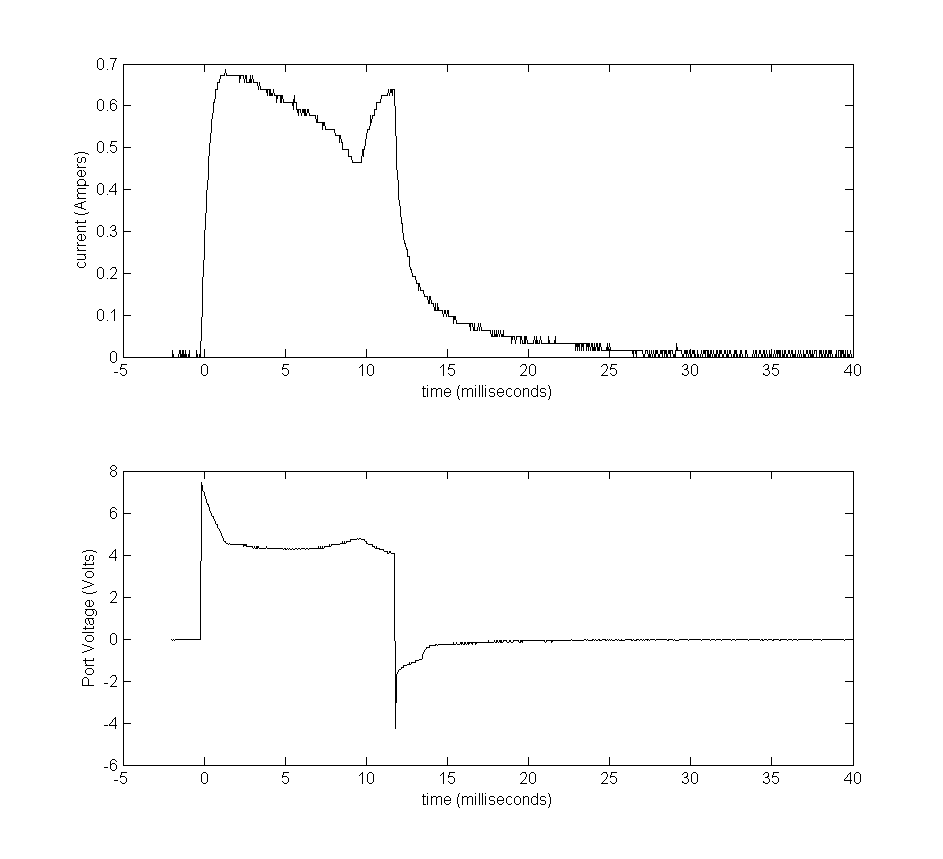

cannon. To understand what exactly is going on, I measured

the port voltages and the current through the solenoid using an

oscilloscope. The graphs below show the results.

As expected, the port voltage goes high almost immediately.

The current ramps up because of the inductance of the solenoid's coil.

This causes the port's voltage to drop from about 7V (The NXT used

rechargeable batteries) to less than 5V. Then the current continues to

drop. I am not sure why, perhaps because of the movement of the

plunger. At some point the current climbs

again, perhaps the result of the plunger reaching the end of its

stroke. When the NXT powers off the port, the current ramps down

gradually (again

due to the inductance), which causes a short negative-voltage spike

until the protection diode in the NXT starts conducting. The protection

diode stops conducting when the votage across it drops to below the

diode's threshold, so the low negative voltage in the port lingers for

a while longer.

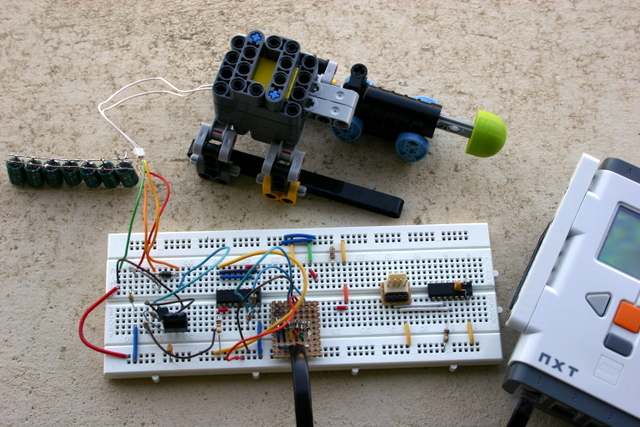

Using a Capacitor to Power the Solenoid from a Sensor Port

The next driving method uses a sensor port rather than a motor

port. This leaves the motor ports available, well, for motors. The

circuit is an I2C circuit so it can be used on the same port with other

I2C sensors.

The key here is to slowly charge a large capacitor using the

4.3V supply, and then to discharge it all at once through the solenoid

to activate it. To work, the capacitor need to

have (1) high enough capacitance to store enough charge to activate the

solenoid, and (2) low enough internal resistance (called ESR) to

discharge quickly enough to generate a large current through the

solenoid.

The graphs above show roughtly how large the capacitor needs

to be.

The

activation above uses about 500mA for 10ms. This is equivalent to 0.005

coulomb of charge. At 5V, a capacitor would need to be 1mF (1000uF) to

store that much charge. In reality, the capacitor would need to be

larger, because as the capacitor discharges, the voltage across it

drops, reducing the current through the solenoid. So the capacitor

would need to be several times larger.

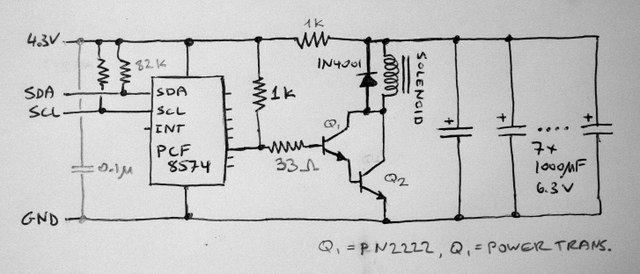

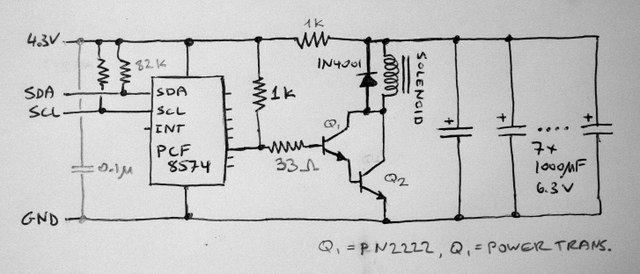

After a few experiments I was able to get it to work. The

circuit slowly charges seven 1000uF capacitors. A PCF8574 (actually a

PCF8574A, which has a different I2C address) controls a darlington

transistor configuration. Most of the time, the transistors should be

off, which essentially disconnects the solenoid from the circuit. When

the 8574 turns its outputs on, this turns on the darlington

pair and discharges the capacitors through the solenoid, thereby

activating it.

The capacitors are charged through a 1k resistor, which gives

a 7-seconds RC constant. In the program, I let it charge for 15 seconds

before firing, to let the capacitors charge more fully. You can use a

larger value resistor, say 2.2k, to reduce the maximum charging

current, but this will also slow down the charging phase.

Turning on the transistors requires a bit of care. The 8574

can only supply about 100uA of current, which is not enough to turn the

darlington pair on completely. The effect that you see on the scope is

(1) the pin of the 8574 does not reach anywhere near Vcc, and (2) the

voltage of the capacitors drops down linearly, which means that the

switching transistor is only allowing constant current to flow, which

in turn means that it is not saturated. I solved this by adding a 1K

pullup resistor to the darlington base, which provides enough base

current to energize the solenoid. But this is an awkward solution since

the pullup resistor is now drawing about 5mA when the capacitors are

charging. Not terrible but still a waste.

An I2C chip like the MCP23008 that can provide 25mA (in any

direction, to Vcc or to ground) would be a better choice here (but I

don't have one right now).

I used a discrete darlington pair (with a high-voltage power

transistor that I removed from an old PC power supply, but you can use

any NPN transistor that can pass 2A or so). To activate several

solenoids, a chip like the ULN2003 or the ULN2803 would be a better

choice: these chips combine 7 or 8 darlington pairs that can pass 500mA

each in a small package. (Thanks to Michael Gasperi who suggested the

use of the ULN2003 for a stepper controller for the NXT.)

If you build a similar circuit, build first a simple test circuit to

make sure that your capacitor(s) have enough capacitance and low-enough

ESR. Charge them slowly through a resistor, and then discharge them

through the solenoid, with a reverse-biased diode in parallel with the

solenoid.

© 2007, Sivan Toledo

A solenoid is a coil that pulls (or

pushes) a metal rod called

a plunger when current flows through it. There are many kinds of

solenoids: pull and push types, with and without springs (to push back

the plunger when current no longer flows), with and without latches,

etc. The main advantage of solenoids over motors is that they can

effect a linear motion using a compact mechanism with no gears. On the

negative side, solenoids have a very short stroke (the length of

movement of the plunger).

A solenoid is a coil that pulls (or

pushes) a metal rod called

a plunger when current flows through it. There are many kinds of

solenoids: pull and push types, with and without springs (to push back

the plunger when current no longer flows), with and without latches,

etc. The main advantage of solenoids over motors is that they can

effect a linear motion using a compact mechanism with no gears. On the

negative side, solenoids have a very short stroke (the length of

movement of the plunger).